November 15, 2025

Optimizing Solvent Consumption in Solvent-Based Inkjet Printers

How Smart Ink Pumps Reduce VOCs, Improve Efficiency, and Cut Operating Costs

1. Introduction: Why Solvent Consumption Matters

Solvent-based inkjet printers are widely used in advertising, signage, coding & marking, and packaging industries due to their high durability and strong adhesion. However, solvent-based inks also bring significant challenges:

• High VOC (volatile organic compound) emissions

• Rising solvent purchasing costs

• Stricter environmental and regulatory requirements

• Increased pressure on long-term sustainability

In all these factors, the ink pump—often considered the “heart” of the printer—plays a decisive role in determining solvent efficiency and overall system performance.

2. Core Factors Affecting Solvent Consumption

Solvent usage varies depending on ink chemistry, printer design, operating conditions, and environmental controls.

Among these, the ink pump has a direct influence on consumption efficiency, evaporation rate, and waste generation.

Below are five key factors where pump performance significantly impacts solvent usage.

2.1 Ink Supply Stability & Solvent Evaporation

A stable and precisely controlled ink flow helps reduce unnecessary solvent loss.

• Accurate flow control prevents over-supply and reduces waste

• Smart pumps adjust delivery volume according to print demand

• Stable continuous flow minimizes evaporation from tubes and printheads

• Variable pump speed ensures optimal ink usage during diverse printing loads

2.2 Ink Viscosity Management

Solvent-based inks naturally thicken as they circulate and evaporate.

• Pumps must coordinate with viscosity sensors for precise solvent replenishment

• Automated compensation prevents manual over-correction

• Poor pump response can cause excessive solvent addition, raising consumption levels

2.3 Sealing Integrity & Leakage Prevention

Even small leaks can lead to serious solvent loss and VOC emissions.

• Proper sealing avoids hidden losses caused by worn O-rings or loose connections

• Accurate negative pressure control prevents backflow or drying printheads

• Reduced drying cycles → Less cleaning → Lower solvent waste

2.4 Ink Recovery & Reuse Efficiency

Efficient recovery systems greatly improve overall ink utilization.

• Pumps should maintain consistent pressure to support solvent recycling

• High-quality filtration avoids clogging and reduces energy consumption

• A well-designed recovery loop ensures unused solvent is reused instead of discarded

2.5 Smart System Optimization

Modern inkjet printers increasingly rely on intelligent control systems.

• Real-time adjustment based on workload and ink condition

• Energy-saving modes lower pump speed during idle periods

• Consistent ink circulation reduces evaporation and VOC emissions

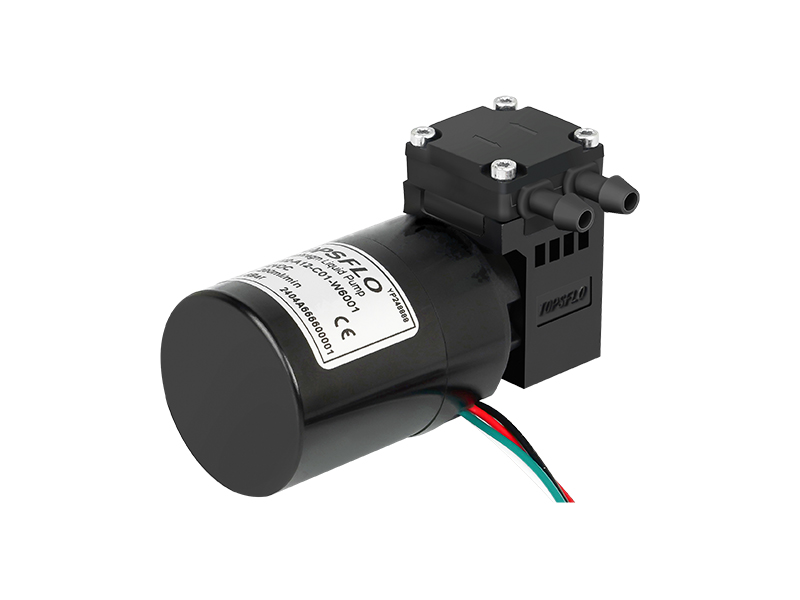

3. Topsflo Smart Ink Pumps: Engineered for Solvent Efficiency

Topsflo’s ink pump technologies are specifically designed for solvent-based inkjet printers, delivering exceptional stability, low solvent consumption, and long-term reliability.

Popular models include: TFSD, TF30B, TF22, TF30A, MG series.

|

|

|

|

|

| ink pump TFSD | ink pump TF30B | ink pump TF22 | ink pump TF30A | ink pump MG |

3.1 Key Advantages

♦ High-Precision Flow Control

Low-pulsation, stable output ensures the printhead receives exactly the required ink volume—no excess, no waste.

♦ Advanced Sealing Technology

Static sealing + enclosed diaphragm structure results in:

• Zero leakage

• Minimal VOC evaporation

• Consistent negative pressure control

♦ High-Performance Motor Design

Topsflo’s proprietary motor solutions deliver:

• Strong durability

• Long continuous-working life

• Stable performance under demanding printing environments

♦ Compliance and Sustainability

Topsflo pumps support companies in:

• Lowering VOC emissions

• Meeting environmental regulations

• Improving solvent recovery efficiency

4. The Sustainable Advantage

Choosing Topsflo ink pumps is not just a technical upgrade—

it’s a strategic investment in efficiency, cost reduction, and sustainability.

Businesses benefit through:

• More consistent printing performance

• Lower solvent purchase and operating costs

• Reduced environmental impact

• Longer equipment life and fewer maintenance cycles

5. Conclusion

💧 Maximize the value of every drop of solvent.

With Topsflo’s precision-engineered ink pumps, businesses gain a reliable, efficient, and environmentally responsible fluid-control solution.

Topsflo — Your professional partner for a brighter, more sustainable future.

6. Frequently Asked Questions (FAQ)

Q1: What causes excessive solvent consumption in solvent-based inkjet printers?

A1: Common causes include unstable ink flow, poor sealing, improper viscosity compensation, high evaporation rate at printheads, and inefficient ink recovery systems. A well-designed ink pump significantly reduces these losses.

Q2: How do smart ink pumps help reduce VOC emissions?

A2: Smart pumps maintain precise flow control, reduce leakage, stabilize negative pressure, and minimize unnecessary circulation. These features reduce solvent evaporation—the main source of VOC emissions.

Q3: Do Topsflo ink pumps support high-viscosity or special solvent-based inks?

A3: Yes. Topsflo pumps are engineered for compatibility with common solvent formulations and can handle varying viscosity levels. Optional materials and customized configurations are available for special inks.

Q4: Can using a high-precision pump reduce operational costs for printers?

A4: Absolutely. Reliable flow control prevents ink oversupply, reduces cleaning frequency, minimizes waste, and lowers solvent purchasing costs. Energy-efficient pump designs further reduce power consumption.

Q5: What pump models are recommended for industrial solvent-based inkjet printers?

A5: Topsflo’s recommended models include TFSD, TF22, TF30A, TF30B, and MG series, offering high stability, strong sealing, and intelligent control options designed specifically for solvent-based printing systems.

Q6: Are Topsflo pumps suitable for OEM printer manufacturers?

A6: Yes. Topsflo provides OEM customization including materials, interfaces, voltage, flow specifications, sealing solutions, and private-label manufacturing for large-scale printer manufacturers.